What is the temperature range of flame retardant sealed insulated wiring duct?

Release Time : 2025-03-04

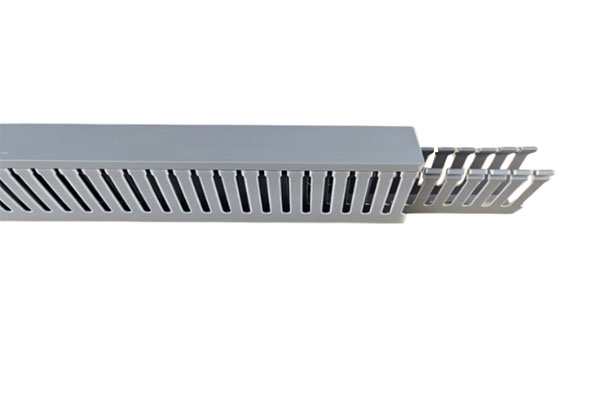

As an important electrical protection material, flame retardant sealed insulated wiring duct plays an indispensable role in power transmission, building wiring and industrial control. Its temperature range, as one of the important indicators to measure its performance, is directly related to the stability and safety of the use of wire ducts at different ambient temperatures. This article will explore the temperature range of flame retardant sealed insulated wiring duct and its influencing factors.

Temperature range of flame retardant sealed insulated wiring duct

The temperature range of flame retardant sealed insulated wiring duct is not fixed, but is affected by many factors, such as material, production process, additives and use environment. Generally speaking, the temperature range of flame retardant sealed insulated wiring duct is between -40℃ and +105℃, but the specific value needs to be determined according to the actual situation of the product.

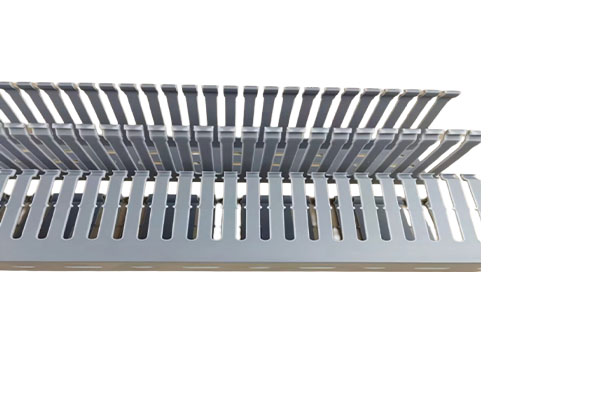

In low temperature environment, the material of the wire duct must have good toughness and brittleness resistance to prevent cracking or breaking caused by low temperature. Flame retardant sealed insulated wiring duct usually adopts materials with good cold resistance, such as modified varieties of polyvinyl chloride (PVC). These materials can still maintain good physical properties at low temperatures, ensuring the normal use of wire pipes in cold areas or low-temperature working environments.

In high-temperature environments, wire pipes need to have good heat resistance and stability to prevent softening, deformation or burning caused by excessive temperature. Flame retardant sealed insulated wiring duct improves its high-temperature tolerance by adding additives such as flame retardants and stabilizers. At the same time, the use of special production processes and formulas, such as high-performance materials such as cross-linked polyethylene (XLPE), can further improve the high-temperature tolerance of wire pipes.

Analysis of influencing factors

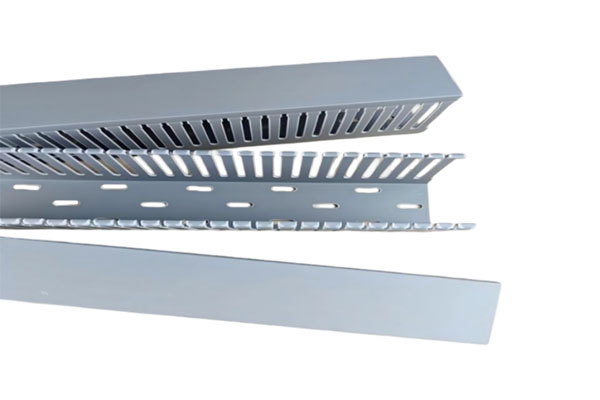

Material: Wire pipes of different materials have different temperature resistance ranges. For example, the temperature resistance range of PVC wire pipes is generally between -15℃ and +70℃, while the temperature resistance range of XLPE wire pipes can reach -40℃ to +105℃ or even higher.

Production process: The production process also has an important influence on the temperature resistance range of wire pipes. By optimizing the production process, such as increasing the extrusion temperature and adjusting the cooling rate, the physical properties and heat resistance of the wire tube can be improved.

Additives: The addition of additives such as flame retardants and stabilizers can significantly increase the temperature resistance range of the wire tube. For example, flame retardants can decompose at high temperatures to produce non-flammable gases, thereby inhibiting the spread of flames; stabilizers can prevent the wire tube from oxidative decomposition at high temperatures.

Use environment: The use environment also has a certain impact on the temperature resistance range of the wire tube. For example, when used in places with high temperature, dust, vibration and fire hazards, wire tubes with a higher temperature resistance range must be selected to ensure the safe and stable operation of electrical lines.

When choosing flame retardant sealed insulated wiring duct, it should be selected according to the specific use environment and requirements. For wire tubes that need to be used in high temperature environments, products with a higher temperature resistance range should be selected; for wire tubes that need to be used in low temperature environments, products with better cold resistance should be selected. At the same time, during use, attention should be paid to regular inspection and maintenance of the wire tube to ensure its stable and reliable performance.

In summary, the temperature resistance range of flame retardant sealed insulated wiring duct is an important indicator affected by many factors. By rationally selecting materials, optimizing production processes, adding appropriate additives, and paying attention to the use environment, the temperature resistance range and performance of the wire duct can be significantly improved.