What special materials or additives are used in PVC cable trunking to improve its fire resistance?

Release Time : 2025-04-16

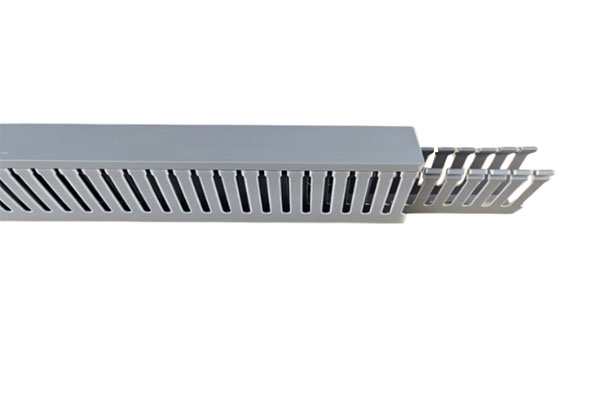

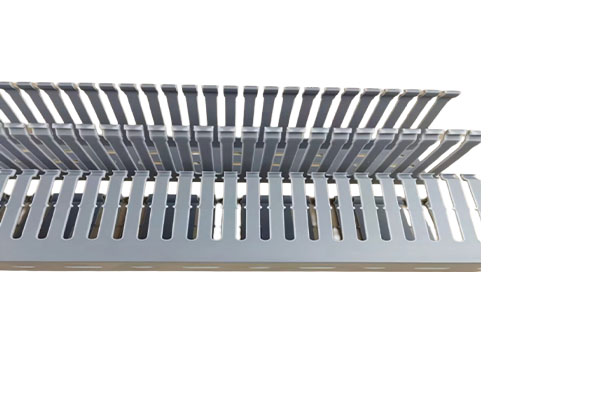

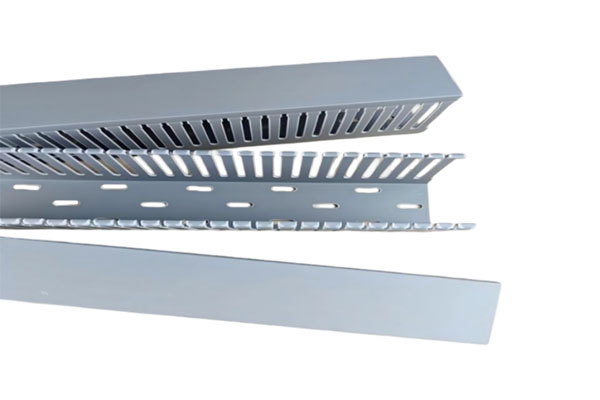

As an indispensable part of electrical installation, the fire resistance of PVC cable trunking is one of the important criteria for measuring product quality. In order to achieve the ideal fire protection effect, manufacturers will use a series of special materials and additives to enhance the flame retardant properties of pvc cable trunking during the production process.

First of all, it is necessary to mention the application of halogen flame retardants. These additives release hydrogen halide gas to form a protective film when a fire occurs, preventing oxygen from contacting combustible materials, thereby slowing down or preventing the spread of flames. Although halogen flame retardants have high flame retardant capabilities, they may release harmful gases during combustion, so modern manufacturing trends gradually tend to use more environmentally friendly alternatives.

Halogen-free flame retardants have become a preferred option. These additives are usually based on elements such as phosphorus and nitrogen. When encountering high temperatures, they can expand rapidly to form a carbon layer. This layer of carbon not only insulates heat but also isolates oxygen, effectively inhibiting the spread of flames. For example, red phosphorus, as a common halogen-free flame retardant, is widely used in various plastic products, including PVC cable trunking, due to its high efficiency. However, due to its dark color and the possibility of affecting the appearance of the finished product, red phosphorus is sometimes replaced by other forms such as microencapsulated red phosphorus to balance aesthetics and functionality.

In addition to the above chemical additives, some physical fillers are also added to PVC substrates to improve their fire resistance. Mineral powders such as talcum powder and wollastonite are typical examples. They not only increase the mechanical strength of the material, but also decompose and absorb heat when heated, reduce the ambient temperature, and delay the decomposition process of PVC. In addition, these fillers can also improve the fluidity and processing properties of the material, making the final product more uniform and stable.

It is worth mentioning that the advancement of nanotechnology has also provided new possibilities for improving the fire resistance of PVC cable trunking. Nano-sized magnesium oxide, aluminum hydroxide and other particles can be evenly dispersed in the PVC matrix. Due to their huge specific surface area and high activity, they can achieve better flame retardant effects at a lower addition amount. At the same time, nanoparticles can also enhance the mechanical properties of composite materials, giving the product better impact resistance and wear resistance.

In addition to formula design, the production process also has an important impact on the final performance of the product. Extrusion molding is one of the main methods for manufacturing PVC cable trunking. Precise control of temperature, pressure and speed parameters in this process is essential to ensure uniform distribution of additives. Good process control can not only ensure the effective dispersion of flame retardants and other functional fillers, but also avoid degradation caused by local overheating, further improving the overall quality of the product.

In short, through carefully selected flame retardants, functional fillers and advanced production processes, flame retardant fine-tooth insulated wiring duct not only has excellent fire resistance, but also takes into account environmental protection requirements and mechanical properties. Whether it is a public building or an industrial facility, choosing the right PVC cable trunking can significantly improve the safety of the electrical system, reduce the risk of fire, and provide solid protection for the safety of people's lives and property. With the development of science and technology, more innovative materials and technologies will be introduced into this field in the future, continuously promoting PVC cable trunking to a higher level of safety and reliability.

First of all, it is necessary to mention the application of halogen flame retardants. These additives release hydrogen halide gas to form a protective film when a fire occurs, preventing oxygen from contacting combustible materials, thereby slowing down or preventing the spread of flames. Although halogen flame retardants have high flame retardant capabilities, they may release harmful gases during combustion, so modern manufacturing trends gradually tend to use more environmentally friendly alternatives.

Halogen-free flame retardants have become a preferred option. These additives are usually based on elements such as phosphorus and nitrogen. When encountering high temperatures, they can expand rapidly to form a carbon layer. This layer of carbon not only insulates heat but also isolates oxygen, effectively inhibiting the spread of flames. For example, red phosphorus, as a common halogen-free flame retardant, is widely used in various plastic products, including PVC cable trunking, due to its high efficiency. However, due to its dark color and the possibility of affecting the appearance of the finished product, red phosphorus is sometimes replaced by other forms such as microencapsulated red phosphorus to balance aesthetics and functionality.

In addition to the above chemical additives, some physical fillers are also added to PVC substrates to improve their fire resistance. Mineral powders such as talcum powder and wollastonite are typical examples. They not only increase the mechanical strength of the material, but also decompose and absorb heat when heated, reduce the ambient temperature, and delay the decomposition process of PVC. In addition, these fillers can also improve the fluidity and processing properties of the material, making the final product more uniform and stable.

It is worth mentioning that the advancement of nanotechnology has also provided new possibilities for improving the fire resistance of PVC cable trunking. Nano-sized magnesium oxide, aluminum hydroxide and other particles can be evenly dispersed in the PVC matrix. Due to their huge specific surface area and high activity, they can achieve better flame retardant effects at a lower addition amount. At the same time, nanoparticles can also enhance the mechanical properties of composite materials, giving the product better impact resistance and wear resistance.

In addition to formula design, the production process also has an important impact on the final performance of the product. Extrusion molding is one of the main methods for manufacturing PVC cable trunking. Precise control of temperature, pressure and speed parameters in this process is essential to ensure uniform distribution of additives. Good process control can not only ensure the effective dispersion of flame retardants and other functional fillers, but also avoid degradation caused by local overheating, further improving the overall quality of the product.

In short, through carefully selected flame retardants, functional fillers and advanced production processes, flame retardant fine-tooth insulated wiring duct not only has excellent fire resistance, but also takes into account environmental protection requirements and mechanical properties. Whether it is a public building or an industrial facility, choosing the right PVC cable trunking can significantly improve the safety of the electrical system, reduce the risk of fire, and provide solid protection for the safety of people's lives and property. With the development of science and technology, more innovative materials and technologies will be introduced into this field in the future, continuously promoting PVC cable trunking to a higher level of safety and reliability.