How is the sealing performance of flame retardant sealed insulated wiring duct achieved?

Release Time : 2024-12-26

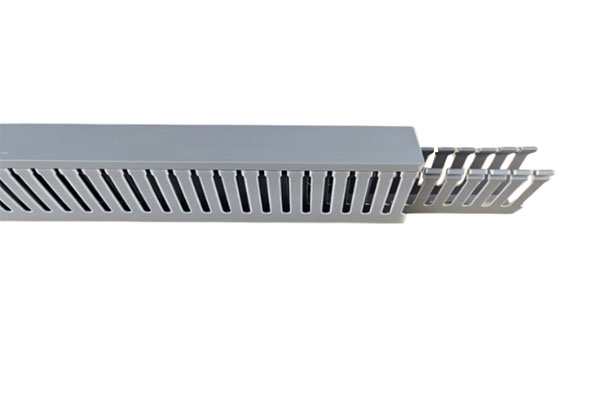

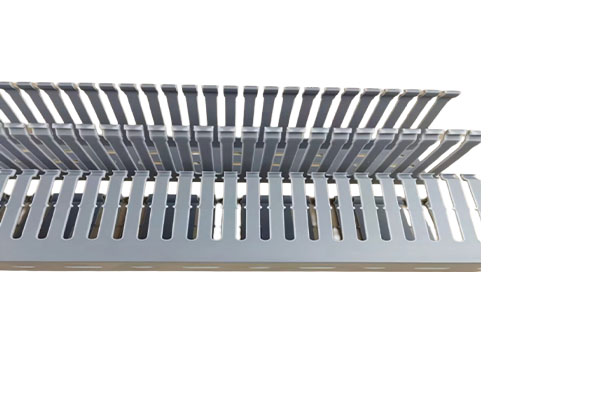

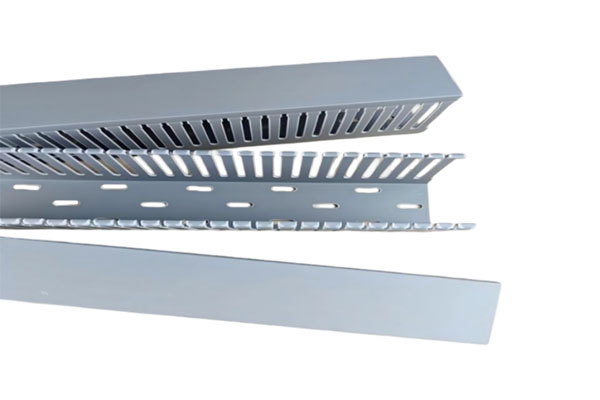

As a vital component of the power system, the role of the wire duct is to protect the wires from interference and damage from the external environment and ensure the stability and safety of power transmission. Among the many wire ducts, flame retardant sealed insulated wiring duct has attracted much attention due to its unique flame retardant, sealing and insulation properties.

The sealing performance of flame retardant sealed insulated wiring duct mainly depends on its special material composition and structural design. This type of wire duct is usually made of plastic materials with excellent flame retardant properties, such as PVC, PE, etc. These materials themselves have good sealing properties and can prevent the intrusion of external gas, moisture and dust to a certain extent. More importantly, during the production process, the wire duct will undergo special processing to form a tight and impermeable film on its surface, thereby further enhancing its sealing performance.

In addition to the selection and processing of materials, the structural design of flame retardant sealed insulated wiring duct is also a key factor in achieving its sealing performance. This type of wire duct is usually in the form of spiral winding or corrugated tube. This design not only enhances the strength and toughness of the wire duct, but also enables it to fit tightly around the wire to form an effective sealing barrier. At the same time, both ends of the wire duct are usually equipped with special sealing joints or sealing plugs to ensure the sealing of the wire at the connection or terminal.

The sealing performance of flame retardant sealed insulated wiring duct is of great significance in practical applications. First, it can effectively prevent external moisture, dust and corrosive gases from invading the inside of the wire, thereby extending the service life of the wire and improving the stability of the power system. This feature is particularly important in humid and highly corrosive environments. Secondly, the sealing performance can also prevent the wire from loosening or falling off due to external forces, ensuring the continuity of power transmission. In addition, in emergency situations such as fire, flame retardant sealed insulated wiring duct can effectively prevent the spread of fire and buy precious time for rescue and evacuation.

In order to achieve a better sealing effect, the flame retardant sealed insulated wiring duct needs to pay attention to the following points during installation and use: First, when cutting and connecting the wire tube, ensure that the cut is smooth and burr-free to avoid the formation of gaps at the connection, which affects the sealing performance. Secondly, the fit between the wire tube and the wire should be tight, without looseness or gaps. During the installation process, special sealants or sealing tapes can be used to perform additional sealing treatment on the connection. In addition, the wire tube should avoid excessive bending or twisting during the laying process to avoid damaging its sealing structure.

In short, the sealing performance of the flame retardant sealed insulated wiring duct is achieved through its special material composition and structural design. This feature is of great significance in practical applications, and can effectively protect the wires from interference and damage from the external environment, and improve the stability and safety of the power system. Therefore, the widespread promotion and use of flame retardant sealed insulated wiring duct in the power system is of great significance to ensure the stability and safety of power transmission.

With the continuous advancement of technology and the continuous growth of electricity demand, the performance and application scope of flame retardant sealed insulated wiring duct will continue to expand and improve.

The sealing performance of flame retardant sealed insulated wiring duct mainly depends on its special material composition and structural design. This type of wire duct is usually made of plastic materials with excellent flame retardant properties, such as PVC, PE, etc. These materials themselves have good sealing properties and can prevent the intrusion of external gas, moisture and dust to a certain extent. More importantly, during the production process, the wire duct will undergo special processing to form a tight and impermeable film on its surface, thereby further enhancing its sealing performance.

In addition to the selection and processing of materials, the structural design of flame retardant sealed insulated wiring duct is also a key factor in achieving its sealing performance. This type of wire duct is usually in the form of spiral winding or corrugated tube. This design not only enhances the strength and toughness of the wire duct, but also enables it to fit tightly around the wire to form an effective sealing barrier. At the same time, both ends of the wire duct are usually equipped with special sealing joints or sealing plugs to ensure the sealing of the wire at the connection or terminal.

The sealing performance of flame retardant sealed insulated wiring duct is of great significance in practical applications. First, it can effectively prevent external moisture, dust and corrosive gases from invading the inside of the wire, thereby extending the service life of the wire and improving the stability of the power system. This feature is particularly important in humid and highly corrosive environments. Secondly, the sealing performance can also prevent the wire from loosening or falling off due to external forces, ensuring the continuity of power transmission. In addition, in emergency situations such as fire, flame retardant sealed insulated wiring duct can effectively prevent the spread of fire and buy precious time for rescue and evacuation.

In order to achieve a better sealing effect, the flame retardant sealed insulated wiring duct needs to pay attention to the following points during installation and use: First, when cutting and connecting the wire tube, ensure that the cut is smooth and burr-free to avoid the formation of gaps at the connection, which affects the sealing performance. Secondly, the fit between the wire tube and the wire should be tight, without looseness or gaps. During the installation process, special sealants or sealing tapes can be used to perform additional sealing treatment on the connection. In addition, the wire tube should avoid excessive bending or twisting during the laying process to avoid damaging its sealing structure.

In short, the sealing performance of the flame retardant sealed insulated wiring duct is achieved through its special material composition and structural design. This feature is of great significance in practical applications, and can effectively protect the wires from interference and damage from the external environment, and improve the stability and safety of the power system. Therefore, the widespread promotion and use of flame retardant sealed insulated wiring duct in the power system is of great significance to ensure the stability and safety of power transmission.

With the continuous advancement of technology and the continuous growth of electricity demand, the performance and application scope of flame retardant sealed insulated wiring duct will continue to expand and improve.